1. Preparation

Inspect the equipment: Make sure that all parts of the metal baler are intact, without looseness, wear or damage. Check whether the hydraulic system and electrical system are normal, and whether there is enough lubricating oil at each lubrication point.

Clean up the site: Clear the debris and obstacles around the baler, and keep the work area clean for operation and maintenance.

Prepare metal materials: Sort and sort the metal waste to be packaged, remove impurities, and ensure that the materials meet the requirements of the baler.

2. Equipment debugging

Connect the power: According to the requirements of the equipment manual, connect the power correctly and check whether the voltage is stable.

Start the equipment: Start the metal baler, let the equipment run without load, check whether all parts are operating normally, and whether there are abnormal sounds and vibrations.

Set parameters: According to the type, size and packaging requirements of the metal material, adjust the relevant parameters of the baler, such as packaging pressure, packaging speed, tightness of the strapping belt, etc.

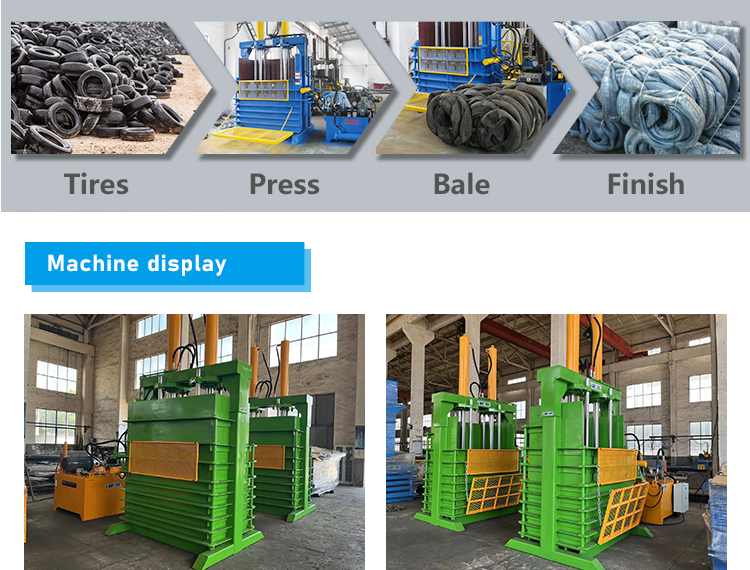

3. Material packaging

Put in materials: Put the sorted metal materials evenly into the feed port of the baler, and be careful not to exceed the maximum feed size and carrying capacity of the equipment.

Start packaging: Start the packaging program, and the equipment will automatically compress and bundle the materials. During the packaging process, the operator should keep an eye on it to ensure that the materials are evenly and tightly packed.

Complete packaging: When the baler completes a packaging cycle, take out the packaged metal blocks and place them in the designated location.

4. Equipment maintenance

Regular cleaning: Regularly clean the body, feed port and discharge port of the baler to remove dust, oil, metal debris and other debris to keep the equipment clean.

Check components: Regularly check the various components of the baler, such as hydraulic cylinders, pistons, sealing rings, strapping rollers, etc. If they are worn or damaged, they should be replaced in time.

Replace oil: Regularly replace hydraulic oil and lubricating oil according to the requirements of the equipment manual to keep the oil clean and perform well.